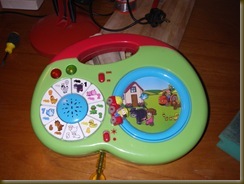

Broken toy number two. More Early Learning Centre, this time an English-French farm toy which died within two weeks of receipt but we didn’t get round to returning.

The thing wasn’t completely dead though, but stuck on same tune. Pressing its buttons lead to very brief halt and restart as did switching between English and French. Also the farm scene was stuck and wee man on tractor was static rather than merrily rotating round scene.

Obviously this was going to be more complex inside than toy #1. On opening up there were a variety of PCBs and a motor unit. Testing the switches, motor, lights and mechanics revealed no obvious problems. Reassembling it got the wee man rotating and tune working but I could not resurrect the interactive component. I guess that this probably means the chip/main PCB is duff. Admitting defeat I stripped it for parts (couple of switches, electrolytic capacitors, transistors, a light (or maybe IR) activated switch, the 6V DC motor and its gearbox, pair of PCB-mounted LEDs, and a ton of screws) and consigned the remains to the recycling bin.

So 1 for 2 on toy fixes, the next is pure carpentry so I’m hoping to pull back my success rate.

Saturday 19 February 2011

Thursday 17 February 2011

Anglepoise Lamp

The playroom tidy has brought forth a Model 90 Anglepoise lamp, and as the workbench is in a dark corner of the room a spot of illumination would seem to be in order. The only problem was that it had a broken elbow joint.

The small square hole on the lower limb is a socket for a plastic lug which had snapped off leading to the lamp disassembling itself every time it moved.

Remaking the part was out the question but, after taking a few measurements, I realised the square hole was just about the perfect size to accept an M4 bolt (I knew it was worth buying 100 of them!). With a bit of trimming a socket could be formed in the plastic to accept an M4 nut and that should stop the elbow joint from coming apart. But no M4 nuts were to be found in the toolbox so back to Screwfix again as a side trip while going to the cinema.

On return 10 mins with a scalpel provided a socket and once the screw had been cut down to size with a hacksaw and checked for any sharp edges the elbow was fixed.

It wasn’t perfect, note the gap between the black plastic elbow and the red metal arm, but it was functional again. If it really starts to bug me I think I will have to go back and trim some more plastic and insert a rectangular metal plate into the area where the nut is. With a hole drilled in the correct spot it should be possible to locate the joint more correctly. But as behoves my stated functional/utilitarian bent, ‘tis gud enuf.’

A quick check with a continuity tester to make sure nothing had come loose or whether the bolt was causing any problems which would lead to electrocution of any of the family members and JOB DONE.

|  |

The small square hole on the lower limb is a socket for a plastic lug which had snapped off leading to the lamp disassembling itself every time it moved.

Remaking the part was out the question but, after taking a few measurements, I realised the square hole was just about the perfect size to accept an M4 bolt (I knew it was worth buying 100 of them!). With a bit of trimming a socket could be formed in the plastic to accept an M4 nut and that should stop the elbow joint from coming apart. But no M4 nuts were to be found in the toolbox so back to Screwfix again as a side trip while going to the cinema.

On return 10 mins with a scalpel provided a socket and once the screw had been cut down to size with a hacksaw and checked for any sharp edges the elbow was fixed.

It wasn’t perfect, note the gap between the black plastic elbow and the red metal arm, but it was functional again. If it really starts to bug me I think I will have to go back and trim some more plastic and insert a rectangular metal plate into the area where the nut is. With a hole drilled in the correct spot it should be possible to locate the joint more correctly. But as behoves my stated functional/utilitarian bent, ‘tis gud enuf.’

A quick check with a continuity tester to make sure nothing had come loose or whether the bolt was causing any problems which would lead to electrocution of any of the family members and JOB DONE.

Subscribe to:

Posts (Atom)